Email us

Call us

01829 760000

Knowledge

Guide to Security Tape

Security Tapes are used across logistics, in pharmaceutical / laboratory companies as well as in general industry, most often as a tamper-evident box tape to provide security and chain of custody through supply chains. In this guide we provide an overview of the types of security tape available, the range of customisation options, as well as the types of applications security tape is most used for.

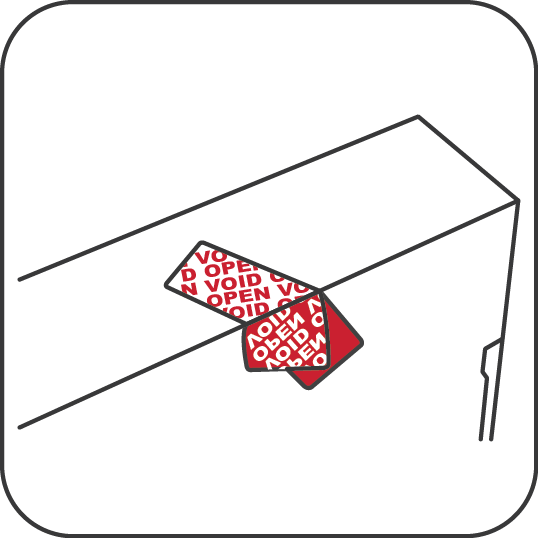

Security box sealing tapes are manufactured with specialised films and pressure-sensitive adhesive, capable of revealing a ‘void message’ on sealed surfaces (such as crate and carton surfaces) upon removal; they can even be used on metal and plastics, for example for security of shrink-wrapped pallets and for sealing cargo containers used in secure airfreight shipments. Upon removal the security box tape the film will also ‘delaminate’, causing the void message to also be shown through the film itself – meaning that opening or tampering is obvious even if attempts are made to stick the tape back down.

Void Message shows through the surface of the security tape as well as in the void message left on the sealed surface

Understanding the Types of Security Tapes

Security tapes are supplied in different formats and styles, and it is useful to understand the distinctions so that you choose the most appropriate and tamper-evident solution possible for your application.

Key Distinction: Overt and Covert Security Tapes

| Overt Security Tape | Covert Security Tape |

|---|---|

|  |

'Overt’ security tape is so-named because this type of tape clearly and ‘overtly’ notifies the handler of the sealed package that security measures have been implemented; this can help to discourage tamper attacks or inappropriate handling in the first instance, due to the risk of identification or disclosure. | 'Covert' security tape has been designed to look like a normal box tape until it is removed; only then do security void messages appear underneath. Covert tape is useful to highlight vulnerabilities in your supply chain, and to trace under whose custody cartons are being opened or tampered with. |

Key Distinction: Continuous security tape vs perforated tape

| Continuous Security Tape | Perforated Security Tape |

|---|---|

|  |

Continuous rolls of security tape are the simplest form of security tape. Security tape is often produced in similar reel formats to standard packaging tapes, e.g. 48-50mm width x 50-66metre long rolls. They can be used in traditional tape dispensers, making them easy to apply to cartons, boxes and so on. | Perforated security tape is generally considered a more secure form of security tape compared to continuous rolls. This type is supplied in segments, typically 10-15cm in length. Each segment has its own sequential security number, meaning that you can seal your cartons or pallets with a particular range of security numbers, for checking against packing lists, manifests etc. |

Key Distinction: Standard vs Customised Security Tape

| STANDARD SECURITY TAPE | CUSTOMISED SECURITY TAPE |

|---|---|

|  |

Standard security tapes are available widely, and can be preferable in scenarios where you did not wish to ‘broadcast’ that a sealed consignment relates to your organisation, brand etc. Branded security tapes can sometimes unwittingly notify fraudsters or thieves of which consignments contain higher value or desirable cargo or goods. | Customised security tape can be supplied with bespoke designs, colours, widths, lengths, and surface and sub-surface prints. Customised security tape can convey brand messaging as well as promote security… Bespoke security tape gives your packaging a ‘premium’ and bespoke feel, particularly for consumer apparel, fashion and electronics. For additional security, it is particularly useful to ‘hide’ security information in the sub-surface void messages – the full customisation options are noted below. |

Key Distinction: Plastic versus Paper Security Tapes

| PLASTIC-BASED SECURITY TAPE | PAPER-BASED SECURITY TAPE |

|---|---|

|  |

| Plastic security tapes continue to be very popular due to their high-tack, water-resistance and bright colours. Our plastic security tapes are manufactured from 30% recycled content plastics and can be readily recycled at end-of-life. | A recent and exciting innovation, paper-based security tapes are sustainable, high-performing and secure. The 100% paper-based tamper-evident tape performs well even on rough and uneven surfaces, and have unparalleled sustainability – reducing your plastic use to 0% and with zero packaging waste per roll. |

Tamper-Evident Box Tapes: Customisation Options

There are countless ways in which your security tape can be customised to suit your application. Bespoke security tape, particularly manufactured with bespoke surface and sub-surface prints, can increase the tamper-evident capabilities of your security packaging, making it more difficult for counterfeiters to replace packaging without leaving obvious signs of tampering.

Below are just some of the customisable features which we can assist with: -

| FEATURE | DESCRIPTION | ILLUSTRATION |

|---|---|---|

| Customised surface prints | Custom printing on the surface of your tamper- evident tape can incorporate your company or brand logos, corporate colours, and other application- or product- specific branding. It can also be used to convey information to users about opening the package - for example that product returns may not be valid if security tape is voided. |  |

| Customised sub-surface prints | The “sub-surface print” is what appears on the sealed surface (i.e. carton, crate or pallet surface) when the security tape is removed… This can be a custom void message, QR Coding, Barcoding and more… Custom messages increase the security of your packaging and can convey bespoke operational or user information for your benefits within your supply chains (including traceability – see next feature). |  |

| Customised Traceability | Unique security numbering in multiple formats (including barcodes, data matrices etc) can be printed onto to the surface or even printed into the sub-surface void message itself. Being able to security seal your cartons and packages with your own bespoke security number ranges can greatly increase traceability and audit control within your supply chains, allowing to identify vulnerable shipments and weaknesses. |  |

| Custom Roll Widths and Lengths | We are able to supply security tape in customisable widths and lengths. Tapes can be produced in widths from 25 – 240mm, and in reel lengths between 10 and 600metres. Specific roll lengths can prove particularly useful for applying a consistent quantity of security tape for each cargo consignment – for example, our 20metre reel pallet security tape provides an appropriate amount of tape to seal a shrink-wrapped pallet consistently each time. |  |

| Complex Colour and Design Options | We can print security tapes using the CMYK colour process (CMYK – Cyan, Magenta, Yellow and ‘Key’ (black)). The mixture of these colours can provide complex and visually appealing security tape designs. |  |

Applications of Security Tapes

Security tapes are used to seal boxes, crates and pallets and many other types of enclosures. Security tape is most commonly used for tamper-evident security for sealing of cartons, pallets and packages in the logistics supply chain…

| SECURITY TAPE ON PALLETS | SEALING CARTONS AND CRATES | GENERAL PACKAGING SECURITY |

|---|---|---|

|  |  |

Due to the critical nature of maintaining the integrity and tamper-evidence of sealed enclosures, security tape is used particularly in the pharmaceutical, food & drink and consumer electronics sectors.

View our Range of Security Tape and Security Labels

Types of Security Seals

The range and different types of security seals and tags can be confusing to the uninitiated, so we have produced the below quick visual guide for understanding some of the key differences, and how particular types of security seals might be suited to use cases in your organisation. For further help and assistance, please contact us at [email protected]

| .png) | .png) |

| Plastic Indicative Seals, 2 types: (1) Pull-Through Seals seal through locking chamber & pull progressively tighter, suitable for sealing of mail & cash bags; (2) Fixed Length Seals form a fixed loop, suitable where over-tightening might cause accidental breakage in transit (such as trailer hasps). | Security padlock seals are fixed length seals which are small and suitable for sealing of small enclosures like trolley apertures, first aid and other equipment kits, security bag zippers etc. They can easily be sealed and broken by hand for quick and convenient application. | Bolt security seals provide barrier control for shipping containers. They consist of a counterpart barrel and pin with duplicate numbering, sealed together and requiring bolt cutters to remove. They must meet ISO17712 high security standards and are suitable for cross-border customs movements. |

|  |  |

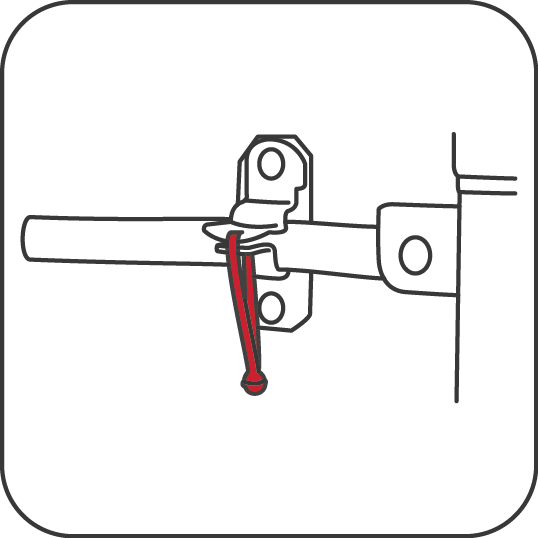

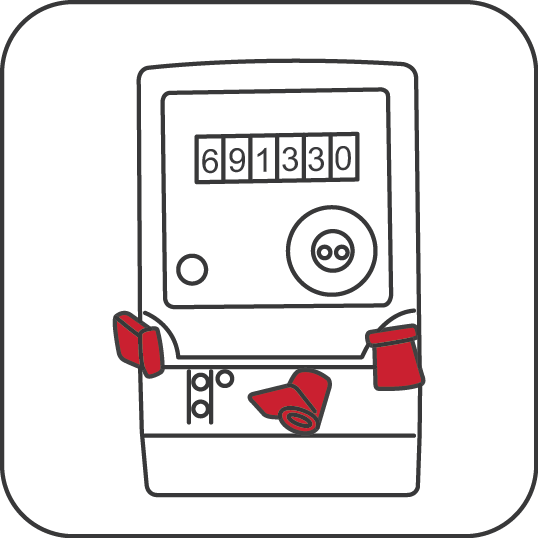

| Metal Cable seals are strong barrier seals, and in their heavier gauge options (Flexigrip 325M and Flexigrip 500M) are also ISO17712 'High Security' approved for customs movements. The pliable wire cable can be flexibly used to seal through hasps and around vertical locking bars, providing increased security. | Metal strip seals are useful option between plastic indicative seals and heavier duty cable and bolt seals - they provide a higher tensile strength of between 50KgF - 100KgF compared to plastic seals, but are most cost-efficient compared to cable and bolt seals. Their thin straps make them well-suited for sealing small apertures, such as TIR cords and railcars. | Meter wire seals are products suited to sealing utility (gas and electric) & taxi meters. They range from simple plastic and metal seals which can be crimped onto sealing wire with pliers, to more sophisticated self-locking seals with inner mechanism. Wire seals are produced with narrow gauge wire to fit through the small apertures of meters (<1mm). |

|  |  |

| Tote box plug seals are a specific type of fixed length seals designed to securely seal the lids of attached lid containers (ALC's) firmly shut. Plug seals seal down flush on to lids, making stacking of tote boxes easier, and can also be produced with paired numbering to seal both of end of the crate with the same security number. | Security labels and tapes are their own category of security seals which work on the basis of their tamper-evident film and adhesive properties, rather than by mechanical anti-tampering. By their nature, they are suitable for sealing flat surfaces, such as carton and pallet seams and edges. | Electronic seals are their own subset of security seals which use electronic sensors to detect a tamper-evident state. They are generally reusable seals with a higher initial cost which is spread over many thousands of uses. |

Our friendly and knowledge team would be happy to discuss your security seals needs - please contact us at [email protected] or +44 (0) 1829 76000.

Security Protocols - Making Security Seals Work for You

Security seals can help to protect your cargo, valuable assets and confidential items. They serve an important role in loss prevention through reducing the incidences of theft, fraud and lost goods. Every year, hundreds of millions of pounds of valuable cargo is lost in such ways – and seals are one way in which these losses can be prevented at a tiny fraction of that price.

However, your cargo and your business are only protected properly when security seals are used as part of your wider supply chain, and due consideration has been made to the complete security of your logistics operations. Most risks which security seals are designed to mitigate – theft, pillage sabotage, smuggling etc – are human behavioural issues, and as such just as much attention should be paid to the humans involved in your security processes as to sourcing the appropriate seal itself.

No matter how well a security seal has been designed, seals only work if you have security at both ‘ends’ – at the point of sealing and at the point of opening – which in turn relies upon the security and reliability of your people. This goes to the very complex issue of organisation’s values and management systems, and how these are communicated to everyone working in the organisation. This of course goes beyond the scope of security seals, but what we can do below is to outline useful pointers to consider when setting up your protocols for security seals and how they fit into your wider supply chain.

Onion Skin Security

The ‘onion skin’ principle is very useful when considering security measures – the idea being that an organisation should have a layered approach to security, so that if one security measure fails, then another will not. For example, consider combining security seals on a larger enclosure such as trailer doors, with security labels on smaller enclosures, such as pallets of cargo or even individual cartons of product.

This can apply not only to physical layers of security seals, but also in security methodologies applied. For example, CCTV in areas where seals are stored, sealed and opened will help you to identify suspicious activity or instances where personnel are not following agreed security protocols.

Custody of Seals

Consider this question: which individual within your organisation is responsible for the purchase of security seals? What would happen if a bad actor within your organisation ordered “copycat” seals for their own nefarious activities and started to use them... would you have systems in place to identify this? Are you using a reputable manufacturer of security seals who have systems to help? This is to illustrate the point that even before security seals have arrived on site, you need to be mindful that seals can be a target for fraudsters. Security seals can act as a false positive that all is well with consignments, and therefore are of value to individuals attempting to hide tampering. The risk increases once seals have arrived to your location, where they are at physical risk of interference. Would you notice if a box of seals was taken by an opportunist?

To minimise risks, security seals should be stored in a secure storage area, ideally with limited access by senior members of your team, and covered by CCTV to pick up any out of the ordinary circumstances. It is recommended that particular seal number ranges are allocated and distributed to designated teams in appropriately sized batches, as necessary for your operations. This can provide a tight audit trail and help to identify vulnerabilities as and when seal tampering / anomalies arise.

Keeping Track of Data

Allied to the above is the importance of recognising that seal numbers are important data which should be collected, collated and stored in a secure way as would be the case with any other type. Keep a controlled record of security number ranges being dispensed out and account for every seal being applied using a documented system.

Using barcoded seals can be useful and is increasingly common. Barcodes can be integrated with barcode readers on PDA’s for automated incorporation into your processes, and reduces the likelihood of human error. If you are using a paper-based system (as is still common for road manifests and bills of lading), make sure that a consistent process is followed, and make copies for archival where appropriate. Consider using seals with duplicated barcode labels on the reverse, which can be simply applied to corresponding manifests / paperwork, rather relying on rewriting or rekeying seal numbers.

Variation

Our seals are highly customisable and can be produced in different colours and with different markings – we can print QR codes, data matrices, logos, barcodes, and many other types of information. Consider using a system of colour or marking rotation, be that on a periodic rotation basis, or using different marked seals for different operations or teams.

Seal Checks

It almost goes without saying, but physically checking seals for tell-tale signs of interference is all-import for the integrity of your supply chain. Fraudsters are ingenious and will try many ways to defeat seals. We produce a ‘known methods of intrusion’ document, available to Universeal UK customers, which can help you to recognise and train your staff in the ways that bad actors attempt to circumvent security seals. Please speak to your Account Manager for further information.

Staff Training and Escalation

Loss prevention and security protocols can only ever be as good as the team implementing them, and efforts need to placed into educating appropriate staff members on the correct way to handle, seal, open and dispose of seals appropriately. Once trained, there should be formal repercussions for failing to report issues with seals as they arrive, for example a failure to report mismatched seals on consignments, anomalies, failures to apply seals, and so on. A system of escalation should also be implemented – if particular members of staff are engaged in a pattern of behaviour or regularly failing to adhere to protocols, this should be flagged and reported to senior levels of management for investigation.

Stay Up-to-date with Legislation

Legislation does and has changed over the last few years, and we recommend using reputable security seal manufacturers who have been long-established and are well-acquainted with industry requirements. Universeal UK is a participating member of ISMA (the International Seal Manufacturer’s Association) and also in the ISO committee responsible for seal standards. We are at forefront of the development of security seals and tamper-evident packaging. We regularly post updates about developments in the field and best practices to our customers, so that they can ensure they are using security seals appropriately.

We hope this guide has been helpful... read on for a full of glossary of terms! Contact us to discuss your security needs today – email [email protected] or call us on +44 (0) 1829 760000.

This article is the third of four, looking at how security seals can fit within your wider security protocols. View Series below...

- What are Security Seals?

- Choosing the Best Security Seal for the Job

- Security Protocols: Making Security Seals work for you

- Glossary – Understanding security seal terminology