At first glance self-adhesive or “sticky” labels don’t sound too complicated, but you’ll be surprised with the range of customisable features to consider when specifying a customised label which will perform for the required application at the optimum cost for your business.

In the below article we note a range of customisable options to consider, from what a custom label is made from to the best type of glue to use to make sure your ‘sticky labels’ stay ‘sticky’!

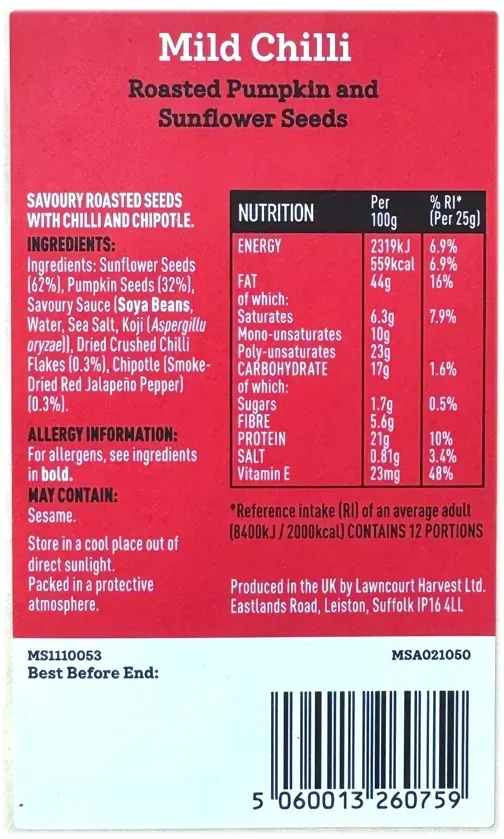

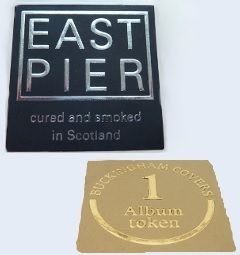

CHOICE OF MATERIALPaper LabelsPaper self-adhesive labels are suited for general use and are biodegradable and cost-effective. Paper labels can also be varnished which provides a degree of protection against everyday hazards such as minor water spillages. Synthetic LabelsPaper self-adhesive labels aren’t always going to be suitable for all needs, particularly if the sticky labels are to be used in outdoor environments, or where any other source of moisture or grease is likely to be present. This is where custom-printed “synthetic” labels are more suitable, most commonly these are manufactured from polypropylene or vinyl base materials. These are similar materials, but different applications do favour one material over the other:- Polypropylene (PP) is a widely used base material available in clear, white and silver colours which can be over-printed, used for its combination of durability, flexibility, temperature resistance and economic cost. PP is also light reflecting which, when combined with inks, can provide vibrant ‘metallic’ gold, silver and copper effects. This can lend a premium and luxury feel to these types of labels. PP labels are most often printed digitally as well as with flexographic technology, depending on the print volumes and the required unit cost. Vinyl (“PVC”) is a longer lasting material compared to PP, used particularly for its excellent resistance to UV rays and moisture. Whereas as PP stickers might expect to last well for 6 months to 2 years, vinyl will last over 5 years. Generally vinyl is produced in white, and over-printed using thermal, digital, screen print or flexographic print technologies. |

|

CHOICE OF ADHESIVEAs standard the adhesives we apply are permanent adhesives with good adhesion across many use cases, although care should always be taken to ensure that labels are applied onto dry surfaces. Where required, we can also supply ‘extra permanent’ high-tack adhesives for even stronger applications, where long-term adhesion is critical to the use case. There are also specialised adhesives which might be of interest for more specific types of applications… Freezer Adhesives These specialised adhesives can go down to low temperatures once applied, but the label must be applied at room temperature to be effective. Freezer adhesives tend to be used on paper substrates rather than synthetic materials, but it should be borne in mind that standard permanent adhesives do already have a tolerance of -18 degrees, so are often sufficient for cold storage purposes. Removable Adhesives As the name suggests, once applied these types of removable labels can be removed at a later date, for instance if applied to book covers. There are also ‘ultra removable adhesives’ too, which leave no adhesive residue at all, and tend to be used in the glass / glazing industries for labelling of panes.

|  |

METHOD OF PRINTThe two main methods of print utilised in the label industry tends now to be digital printing and flexographic printing. Digital printing is an ideal method for short runs and multiple print layouts, up to quantities up to 20,000 labels. Digital lends itself particularly well to full colour as well as variable print – prints including barcoding, numbering, QR coding and any other dynamic information required. Flexographic printing is generally used for much larger runs. Printing plates are required using this method for each layout and colour employed, so it is not so well-suited for multiple print layouts, as print plate costs are significant and any change to the print necessitates a new plate. The flip side is that, in volume, this method results in much lower unit costs for bulk requirements. Additional print options.. as noted above, silver paper and PP materials can be printed with special inks to give a metallic effect, e.g. gold or any other metallic colour. We can also hot or cold foil onto a label with a silver or gold metallic foil if there is an area that is required to have a stamp type image on it. |

|

LABEL FINISHESWe can supply label varnishes and laminations depending on the aesthetic effects and protective qualities preferred by the customer: Varnish: Label varnishes can be applied in matt, gloss or satin finishes. These offer a degree of protection to a label as well as increasing its aesthetic value. Lamination: Laminating a label provides a more robust layer to a label. Generally lamination is a process applied to a synthetic material such as a polypropylene or vinyl for added moisture resistance. Lamination is available in gloss or matt depending on the effect preferred. Domed: A high quality printed vinyl label has a clear liquid resin bubble applied over the top to give a domed or bubble shape. An extra permanent adhesive is standard. |  |

LABEL PRESENTATIONDepending on the type of label used and your requirements, we can supply labels in reel format or as sheets. Roll labels are normally best if you are intending to use label applicators, and even if not, they are often more handy to hand apply by unwinding and unpeeling from the reel. Sheet labels on the other hand can be printed using standard inkjet and laser printers, so are perfect for smaller in-house runs where labels can be printed up as required. |

|

Contact us on [email protected] or give us a call on 01829 760000 to discuss your self-adhesive label requirements.

_1140.webp)