Lockout devices are a key component in industrial settings during maintenance, repair and inspection. But what is a lockout device, and how can it protect workers from harm? In this guide, we’ll explore how lockout devices work, the types available, and how to use them as part of a lockout tagout procedure to maintain high safety standards.

Understanding Lockout Devices

In industrial environments, safely managing machinery and equipment during maintenance or repair is essential to protect workers from hazardous energy sources. Unexpected startup or the release of stored energy can cause serious injuries or fatalities.

Lockout devices play a critical role by physically securing energy isolating devices in a safe position. They help prevent accidental activation and ensure equipment remains de-energised and properly locked throughout servicing. Understanding what lockout devices are, how they work, and their importance within energy control procedures is vital for maintaining workplace safety and compliance with established safety practices.

What Is a Lockout Device?

A lockout device is a safety mechanism used to secure a valve, lever, circuit breaker, or other energy isolating device in a fixed position. This prevents the accidental release of hazardous energy, such as unplanned machinery activation or the uncontrolled flow of gases or chemicals during maintenance or servicing activities.

Industrial equipment can store energy in many forms, including electrical, thermal, hydraulic, or pneumatic. Without proper control, this residual or stored energy can present significant risks. Lockout devices keep equipment in the off position, ensuring energy sources cannot be reactivated while work is underway.

For example, a lockout device applied to a line valve in a facility carrying hazardous substances prevents leaks or exposure. Likewise, locking out a machine’s power source stops it from starting unexpectedly during inspection or repair, protecting technicians from harm.

Many lockout tagout devices allow multiple padlocks to be attached. This means each authorised employee or engineer can apply their own lock, ensuring equipment cannot be re-energised until all parties have completed their tasks and removed their locks. This supports safe procedures and regulatory compliance.

Why Are Lockout Devices Important?

Lockout devices are essential for worker safety and legal compliance. Their main function is to isolate equipment, control hazardous energy sources, and prevent accidental startup during maintenance or servicing.

Accidents often happen when energy sources are not properly shut down or isolated. This can lead to unexpected movement, accidental activation, or the release of stored energy. Using lockout tagout devices according to proper LOTO procedures reduces the risk of serious injuries or fatalities caused by unsafe equipment handling.

Lockout devices ensure maintenance follows an established safety procedure. When combined with appropriate signage and safety tags (as well as proper training) they form part of a comprehensive lockout program that protects affected employees and authorised personnel from exposure to hazardous energy.

Besides protecting people, these devices help businesses meet legal requirements. Effective lockout procedures also reduce downtime, improve operational reliability, and strengthen workplace safety culture.

Simply put, lockout tagout protocols are crucial in preventing unauthorised removal, accidental start up and workplace accidents. They are a frontline defence in maintaining safe industrial environments and preventing unauthorised access.

How Lockout Devices Work

Lockout devices are specialised safety locks which prevent movement of equipment in one or more direction, depending on the nature of the equipment and how it is activated. The lockout safety device isolates the energy source and keeps it in the off position, preventing power, pressure, or thermal energy from being restored. For example, locking a line valve in the closed position stops the flow of liquids or gases, reducing the risk of activation or hazardous energy release.

Multi-Lock Systems for Worker Safety

Typically lockout devices have multiple points of locking, so that they can only be removed once all engineers or safety managers have removed their own respective seal or padlock from the lockout device. This can be particularly helpful where different engineers will carry out different tasks, or whereby any alterations will undergo supervisor or management safety checks as part of a LOTO ("Lockout Tagout") program.

For example, most of our lockout hasps and cable lockouts allow numerous padlocks to be attached. Each affected employee or authorised personnel applies their own lock, preventing accidental start up and ensuring safety. This ensures all workers involved in maintenance follow proper lockout procedures and lockout protocols to maintain safety.

Examples of Accidents Without Lockout Procedures

An engineer is crushed because a conveyor belt activates mid-inspection. A valve opens during repairs, releasing high-pressure chemicals. An electrical arc flash occurs due to an incomplete electrical lockout. In each case, the lack of an energy isolating device or failure to follow LOTO protocols can result in life-altering injuries or fatalities.

Key Components of a Lockout Tagout Procedure

1. Energy Isolation

Before applying a lockout device, the machinery must be de-energised using energy isolating devices such as circuit breakers, selector switches, or bolted slip blinds.

2. Locking and Tagging

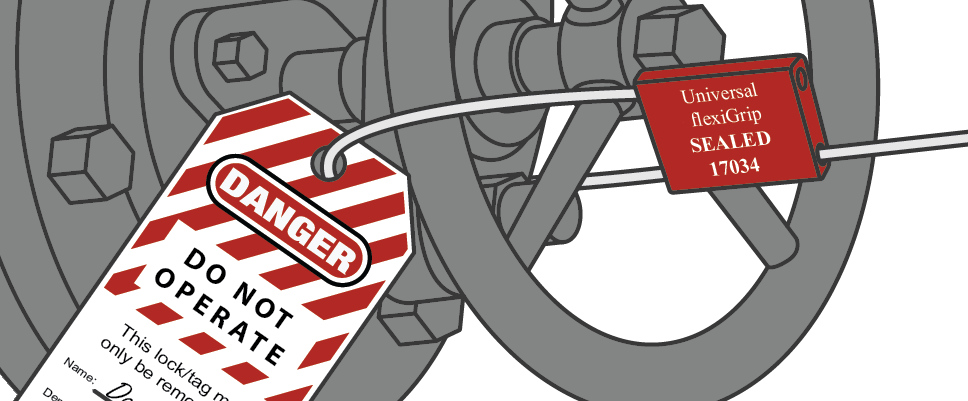

Once isolated, the equipment is secured using the appropriate lockout tagout device, along with a prominent warning device, typically a lockout tag, to indicate who locked it and why.

3. Verification of Isolation

Verifying that residual or stored energy has been discharged is crucial. This step ensures the equipment is in a safe mode and will not activate during servicing.

4. Completion and Re-Energising

The relevant maintenance, inspection or repair is carried out by the qualified technician(s), and is verified by a suitably authorised safety officer. Only after all authorised personnel have removed their locks can the system be returned to normal production operations.

Types of Lockout Device

Our range of lockout devices is designed to suit diverse industrial needs, providing reliable energy isolation and enhanced worker safety across different settings. Whether you need to secure valves, circuit breakers, or other energy isolating devices, our selection includes versatile options such as universal valve lockouts, ball valve lockouts, gate valve lockouts, cable valve lockouts, and security connectors.

| Universal Valve LockoutsUniversal Valve Lockouts provide effective lockout of energy sources. The are available with and without arms and cable attachments for use on many valves, including quarter-turn, butterfly, gate valve, and 3, 4, 5-way valves. They can be sealed using hasps and safety padlocks to ensure that they cannot be removed without following approved procedure and compliance. |

| Ball Valve LockoutA two-piece sliding ball valve lockout device is used to fully encompass a ball valve handle to secure it from unintentional or unauthorised activation by keeping the handle in the off position. They are made from an ABS material which is highly durable, crack-proof, weather resistant and abrasion-resistant. |

| Clamshell Gate Valve LockoutsGate Valve Lockout devices have a clamshell design, completely encompassing a gate valve for effective lockout of energy sources. Once locked, using a padlock, hasp or security seal, the clamshell rotates freely around the hand wheel, preventing it from being turned. They come in several different sizes for optimal fit. |

Cable Valve Lockout DeviceLockout cables provide an effective lock out solution for all manner of gate valves, handles and oversized equipment. They ensure that all energy sources are secured in the ‘off’ position while essential inspection and maintenance is undertaken. They are particularly effective for safely locking out a series of valves in one operation. | |

Car SealsCar seals for the lockout of valves are strong, single-use security devices which effectively lock safety valves in place. They work well where the valve or actuator in question is non-standard or in an awkward position, as car seals only require a simple tethering point to function well. Car seals perform well as single-use lockout devices to seal a valve in the open or closed position, typically for long durations | |

Valve Lockout Security ConnectorsValve lockout security connectors provide a re-usable way of encasing industrial connectors and valves to prevent their misuse or tampering. The y come in two separate parts to allow for easy install, and are secured in place around the valve by use of a meter seal - each connection cannot be accessed without first removing the associated security seal. | |

Steel and Nylon Lockout HaspsSafety Lockout Hasps allow for the lockout of an energy source with multiple securing devices, such as security seals or keyed different safety padlocks. They incorporate a wrap hook, to prevent brute force attempts to access. Nylon safety lockout hasps allow for the lockout of an electric energy source with multiple safety padlocks. Power cannot be restored until all checks and safety padlocks are removed. The dielectric nylon has is non-conductive, protecting discharge of energy through the padlock. |

Supporting Equipment for LOTO Procedures

Safety Warning Tags

Lockout tags are a crucial part of lockout / tagout regimes, communicating key safety-critical information to employees including who is responsible for locking and removing the valve. They are made of PVC to be hard wearing.

Plastic Shackle Padlocks

Safety padlocks are widely used widely in the chemical, electrical, automobile and other industrial sectors. The non-conductive, plastic construction makes it particularly suited to use in electrical lockout applications, where there is a risk of unsafe electrical discharge.

LOTO Boxes and Group Lockout Kits

Where many workers are involved, a LOTO box can hold a single key to a device. Each worker applies their padlock to the box, ensuring no single person can unlock the equipment alone.

Regulatory and Safety Considerations

Ensuring compliance with regulatory requirements and safety standards is a fundamental aspect of any effective lockout tagout program. Regulations in the UK set clear expectations for employers to maintain machinery in a safe condition and protect workers from hazardous energy during maintenance and servicing activities.

Alongside legal obligations, proper training of affected personnel and authorised employees is crucial to understand the risks involved and to correctly implement lockout procedures. By prioritising regulatory and safety considerations, organisations can foster a safer work environment, reduce accidents, and ensure ongoing compliance with industry standards.

Meeting Work Equipment Regulations

In the UK, legislation requires employers to ensure that machinery is safe to use. Lockout procedures form part of this legal requirement. Relevant legislation includes the Health and Safety at Work Act 1974 (HSWA) and Provision and Use of Work Equipment Regulations 1998 (PUWER).

Ensuring Proper Training

Training all affected employees and authorised personnel is essential. Staff must understand the risks of hazardous energy and how to use lockout tagout devices correctly. Conducting regular audits and reviews of LOTO procedures, staff training, as well as safety culture generally, helps to ensure that high standards are implemented and then maintained.

Summary

From isolating energy at the source to preventing accidental startup, lockout devices are critical for maintaining workplace safety. A proper lockout tagout system, complete with the right tools and training, helps organisations protect workers, reduce downtime, and prevent accidents during critical servicing activities.

Investing in LOTO protocols and using the correct lockout tagout devices is more than a compliance measure; it’s a commitment to worker safety and operational excellence.

Need help choosing the right lockout equipment? Get in touch with Universeal’s team today to learn more about our full range of lockout devices, padlocks, tags and LOTO kits designed for your industry.