Email us

Call us

01829 760000

A Guide to Cable Security Seals

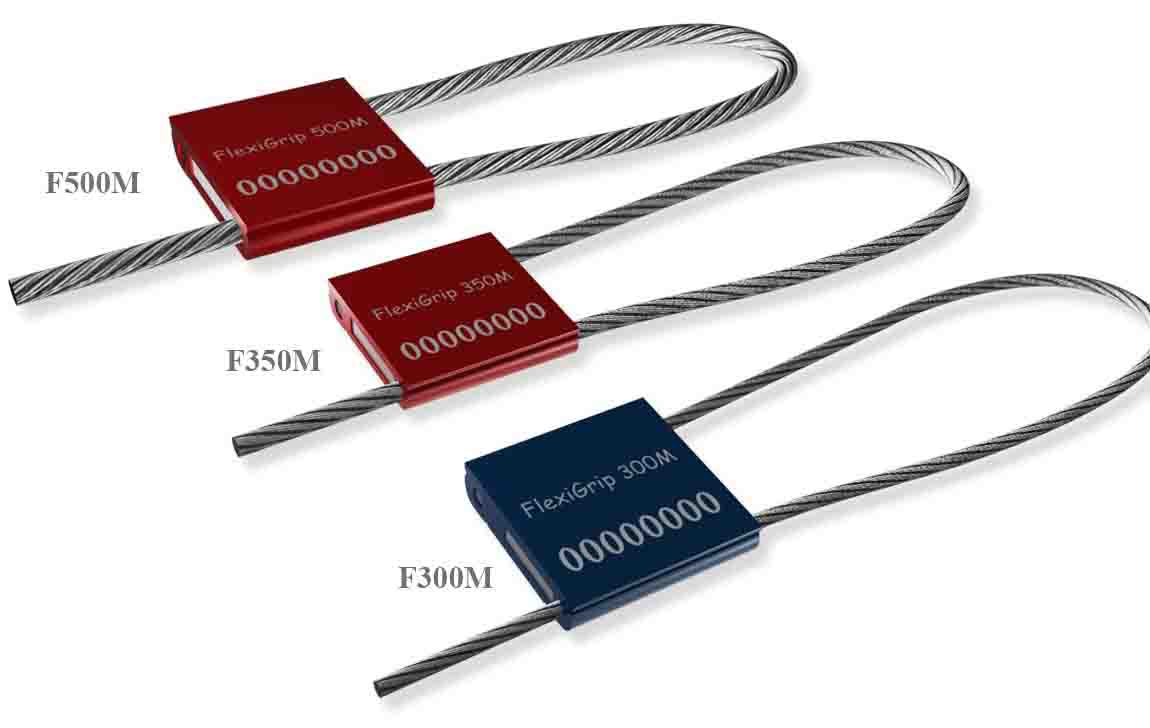

In this article we explore the ‘flexibility of the flexiGrip’ – giving you an in-depth look into our range of metal cable seals used across the world, the benefits of using cable seals for your security, and the wide range of customisation options available to you.

What are Cable Seals?

Cable security seals, also known simply as ‘cable seals’ or wire rope seals, are flexible and strong types of security seals popular across all types of industries, including freight and transport, food and pharmaceutical, industrial and manufacturing and other sectors.

Cable seals generally consist of a metal or plastic body, with the cable / wire rope permanently cinched or clamped at one side of the body, and with a one-way tamper-evident locking chamber at the other end of the body. The wire rope is inserted into this locking chamber and progressively tightened to suit the application. The seal can only be opened by cutting the cable; our cable seals feature non-preformed cable which frays when cut, preventing re-insertion and providing a clear indication of seal tampering.

Why use Cable Seals?

One of the chief benefits of metal cable seals is the combination of the strength and flexibility of the wire cable construction – a cable seal can be tailored in terms of its diameter and length so that it may provide an effective tamper-evident sealing solutions for many applications – from small-scale drums and crates, and all the way through to heavy-duty sealing of shipping containers.

Thinner cable diameters (< 2.5mm diameter cables) are pliable and flexible, and are ideally suited to small-scale applications, whereas heavier gauge 3, 4 and 5mm diameters are much stronger, and can securely seal large-scale sealing applications, such as around container locking bars, or large valve lockout applications.

Cable seals, from lightweight 1.5mm diameter to heavyduty 5mm cable diameter

Cable Seals versus Plastic Seals

Cable seals have much higher pulling strengths than plastic pull-through seals which are sometimes used in their place – some of the strongest plastic pull-through seals might have pulling load resistances of up to 50KgF, but even the most light-weight cable seals are twice as strong as this, and our strongest cable seals (the 325M and 500M) are over 20 to 50x times stronger than plastic seals! This makes them ideally suited to use cases where it is important that seals do not accidentally break in transit, for example crates which are being transported in vehicles.

Security and High-Security Classification Cable Seals

Another benefit of cable seals over plastic seals are the ISO and other national security standards that our cable seals are certified to. The Flexigrip 150M cable seal is certified by the Security Seal Testing Authority (SSTA) as an accepted HMRC customs seal, and for international shipping containers sent by sea freight, our Flexigrip 325M & Flexigrip 500M seals are ISO17712 'H' High Security Classification and C-TPAT compliant - suitable for US customs entry. These certifications make cable seals more suited to customs movements.

Our Range of Cable Seals

flexiGrip cable seals are available in many configurations, including metal or plastic bodies, and in cable diameters from 1.5mm up to 5mm. Below chart provides an overview of our range…

Cable Seal Model | Cable Diameter | Load Resistance | ISO17712 Class | Use Cases |

1.5mm | 101kg | Indicative | Road and Rail Freight, Cargo Trucks, Postal and Mail Sacks, Drums, IBC’s, Airline Trolleys, Drums, Boxes, Cash Bags | |

1.5mm | 259kg | Indicative | ||

1.8mm | 400kg | Indicative | ||

1.5mm | 256kg | Indicative | HMRC Customs, Bulk Tankers, Railway Cars, Valves, Drums, Open Top Barrels | |

2.5mm | 413kg | Security | Bulk Tankers, Valves, Drums, Open Top Barrels | |

3.25mm | 1193kg | High-Security | ISO17712 Customs Movements, Shipping Containers, Bulk Tankers, Industrial Valves

| |

5mm | 2039kg | High-Security | ISO17712 Customs Movements, High Value Shipping Containers, Bulk Tankers, Industrial Valves, Railway Cars, Heavy-Duty Sealing,

| |

5mm | 2039kg | High-Security | ||

1.5mm | 256kg | Indicative | Pallet and Crate Security, APHA movements

|

Customisation Options

| FEATURE | DESCRIPTION | ILLUSTRATION |

|---|---|---|

| Custom Cable Length | We can produce our cable seals with extra-long lengths, such as 2metres. These long length cables are useful for large-scale valve lockout applications, and for sealing around the vertical locking bars of shipping containers and trailer doors. |  |

| Cable Material | As standard we supply with galvanised corrosion-resistant steel – however, for increased corrosion resistance we can also offer in full stainless-steel cable options, particular suited to marine and maritime applications. |  |

| Custom Engraving | Customisation options are endless, including but not limited to :-

|  |

| Colour Customisation | We offer 12 standard colours as standard, to enable customers to take advantage of colour-coding in their operations |  |

| Counterpart Labelling | We can produce cable seals with counterpart labels for duplicate barcode numbering, for application of labels onto paperwork etc. This can reduce possibility for mistakes due to human error / transcription errors. |  |

| ABS Encapsulation | Available on 325M and 500M models, we can produce cable seals with fully encapsulated ABS overmouldings, protecting the laser-engraved anodised aluminimum surface, for the ultimate tamper-resistant cable seal solution. |  |

You can also view our guide to the Top 10 Applications for Cable seals here.

Please contact us on +44 (0) 1829 760000 or [email protected] to discuss your cable seal requirements today.

Types of Container Seals

Most shipping containers transiting around the world will be sealed by way of a High-Security Bolt Seal, and with good reason. Bolt seals are inexpensive but strong barrier seals which cannot be opened except by application of heavy-duty bolt cutters which physically and permanently destroy a security seal, making reinstatement impossible. Bolt seals are required for international customs movements and must conform to internationally agreed standards for manufacturing good practice, strength and tamper-resistance, as stipulated under ISO17712 “High-Security” and C-TPAT Regulations.

However, bolt seals are not the only kind of security seal which can be used, and for certain types of shipments or in particular scenarios it is more suitable to use other types of security seals for sealing shipping containers, and in this guide we explain why this is the case.

| Type of CONTaiNER security seals | illustration |

|---|---|

Bolt seals are the original form of security seal for shipping containers. They are made up of two separate parts which include the bolt pin and the barrel, supplied together and with counterpart seal numbers engraved on each part. Container bolt seals are locked by pushing the pin into the barrel – the barrel has a self-locking system, and once sealed cannot be opened again; a bolt cutter must be used to open the seal, which permanently destroys the seal and makes reinstatement impossible. |  |

The Fork Seal is another type of seal fully-compliant to ISO17712:2013 HSS (high security seal) for sealing shipping containers. Fork seals provide complete wrap-around protection of container locking bars of any size and offers the highest form of container security; the strong steel can only be cut at the designated cutting point using the very heavy-duty bolt croppers. As one of the stronger barrier seals available on the market today, Fork seals are preferred by some users when sending high-value or high-target shipments globally; for example, shipments of whiskey and other high-value food & drink specialities, as well as valuable or sensitive pharmaceutical shipments. |  |

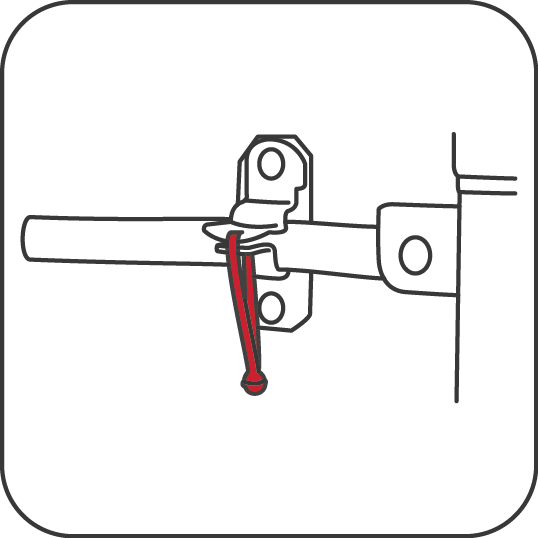

Cable security seals, also known simply as ‘cable seals’ or wire rope seals, are flexible and strong types of security seals. Our higher strength cable seals (>3.25mm diameter) are as suitable for high-security sealing of shipping containers as bolt seals because they conform to the same ISO17712 High Security standards. Indeed, cable seals can be a higher security solution than bolt seals, because their flexible wire construction and customisable lengths mean that they can seal around vertical locking bars, rather than through container door locking hasps/ cams, which can be susceptible to tamper attempts. As long as a cable seal is progressively tightened as tightly as possible then both doors are sealed shut and cannot be opened, regardless of any attacks on locking hasps or locking cams. Additionally, we also supply our double-locking Flexigrip 500MD, which provides two locking mechanisms within one seal, for a superior sealing solution. |  |

Our Globe seal is a robust all metal strip security seal, providing secure protection for shipments in transit, including for sealing of trailer doors and railway cars. It is a reliable and immediate indicator that goods have been received as sent. The seal features a locking mechanism totally enclosed in the head, which is secured by two independent spring rings. The seal is applied without the need of tools and is certified as an ISO17712: 2013 'indicative' classified security seal. |  |

Plastic Security Seals for Shipping Containers Plastic seals are indicative in nature – whilst they provide clear evidence of tampering, they can easily be cut and broken, and so serve as a visual indication of tampering rather than being a barrier to entry. As such, they are often thought to not be appropriate for container security. However, this is not always the case! Shipping containers are not always under customs control; once shipping containers have arrived to port and have been customs cleared, they have entered into free circulation into the domestic market, and are making domestic onward journeys, in a similar way to road haulage trailers. Plastic security seals can then serve as a tamper-evident, easily accessible solution which continues to provide a level of security to the container, without being as heavy-duty or costly as container bolt seals. Another example is using a plastic security seal a tamper-control check on empty containers returning to depots or terminals. Popular models include our DoubleLock seals and FleetLock seals. |

|

Container Locks Keyed Container Locks are the strongest possible types of lock, because they are keyed and are designed to be used many times over many shipping container consignments. Like all keyed locks, container locks have a disadvantage in that it relies upon of appropriate security and availability of the access key; but they do have their uses in particular scenarios - please contact us should you like further information on the types of container locks we can supply. |  |

Display

per page

How to Securely Seal your Shipping Containers

A Guide to Shipping Container Security

One of the worst nightmares for any shipper or receiver of a shipping container: your vessel arrives as expected to port, but on unloading the shipping container it becomes apparent that the security seal used to seal the container is not in the condition expected, and cargo has been interfered with, stolen or otherwise compromised.

In this article we provide some helpful explanations and examples of how you can make sure you select a suitable shipping container seal capable of protecting your cargo; how to apply security seals properly, and other considerations to look out for to ensure security seals provide maximum protection to your goods.

The Rise of Shipping Containers

Containerisation emerged as the standard for global sea freight in the 1970s, revolutionising how sea cargo was handled and transported. Its chief innovation was to simplify the handling of endlessly varied types of cargos – by first packing cargo into discrete, standardised shipping containers suddenly freight could be handled and stacked with ease, regardless of its contents. This helped to greatly increase the efficiency of the global shipping industry and led to a huge increase in global trade. Today, shipping containers make approximately 200million trips per year, and shipping container security has become crucial in protecting global supply chains against fraud, theft, drug trafficking, counterfeiting and terrorism.

But the shipping container introduced new problems… for instance, how could shipping lines keep track of what was in each shipping container? And how could governments and customs authorities be sure that what was in a container was safe and properly declared? How could customers be sure that what they had paid for had actually arrived in tact, and without loss, theft or other mishandling? Record keeping and security had to keep up with the innovation, and the Universeal Group were involved in the design of some of the first generation of shipping container security seals to assist in this aim.

What are Container Security Seals?

Simply put, a container seal is a one-use tamper-evident ‘lock’ for a shipping container door, made to withstand the rigours and harsh conditions experienced during global sea freight, and safeguard the container on its journey. Each security seal has a unique security identification number, and once sealed can only be opened by breaking the seal permanently, making reinstatement or re-use impossible.

Today, security seals are required by customs authorities and shipping lines all over the world as a pre-requisite for the movement of shipping containers. The security seal is a crucial part of shipping container security, and it is for this reason that every shipping container has at least one seal applied before shipping. Container security seals alerts stakeholders to potential theft of goods, reduces fraud and counterfeiting, and minimises the risk of unauthorised access. For this reason, Universeal Group continues to evolve our range of bolt and other container barrier seals to meet modern security concerns and produce hundreds of thousands of barrier seals every year.

Which Types of Security Seals Should be Used?

Shipping containers should only be sealed for international freight movements using "barrier seals": security seals designed to provide tamper-evident security and act as a physically strong one-time ‘barrier’ to entry, delaying intrusion to opportunists who might try to access shipping containers. Barrier seals should be ‘high-security’ classification, as certified to ISO17712:2013 standards. ISO17712 High Security Seals are manufactured to an internationally recognised standard which sets out the tamper-evident and physical strength properties which seals should conform to; for example, they should withstand a tensile strength of over 10kN, amongst other requirements.

It is also important to note that certain shipping lines (Maersk Line, CMA-CGM, MSC etc) have their own particular security policies in place, and when in doubt it is best to check with a representative of the respective shipping line as regards suitability of certain types of seals. Further regulations are laid out in the International Ship and Port Facility Security Code (ISPS) and the US Customs-Trade Partnership Against Terrorism (C-TPAT) program, and the security sealing requirements under these regulations have widespread international adoption.

The Bolt Seal – the Container Seal

Different types of barrier security seals can be used in different scenarios on containers, and we have a guide for this also. However, by far the most popular form of seal is the bolt seal, a barrier seal of pin and barrel type construction, and in this article we focus on this type of barrier seal for international shipping.

Bolt seals are made up of two separate parts which include the bolt pin and the barrel. Both parts should be supplied together and have counterpart seal numbers engraved on both parts of the seal…

|  |

Bolt Seal - pin and barrel | Counterpart duplicate numbering |

You should check that your supplier of security seals marks the serial number on the top of the pin head as shown in the images above… certain suppliers only supply less secure bolt security seals with markings down the length of the pin… this is obscured once sealed… (as below image). If the seal number is obscured, how can you be sure the serial number on the pin actually matches the barrel of the seal, and hasn’t been cut and replaced?

An example of a bolt seal with sequential numbering duplicated along the length of pin - obscured by the locking hasp when sealed in place. If the seal number is obscured, how can you be sure the serial number on the pin actually matches the barrel of the seal, and hasn’t been cut and replaced? Always make sure you use bolt seals engraved with security numbering located on the pin head instead!

Should I Customise my Bolt Seal?

One particular option you may wish to consider is the option to have your bolt seals custom-marked, with a bespoke marking such as your company logo along with custom barcoding or serial number ranges. You can also consider using particular seal colours on rotation, or pre-fix codes for certain kinds of shipments – these types of measures can reduce the ability of fraudsters to replicate seal numbers from blank seals.

How do you Seal a Shipping Container?

Engaging the Seal

Container bolt seals are locked by pushing the pin into the barrel – the barrel has a self-locking system, and once sealed cannot be opened again; a bolt cutter must be used to open the seal, which permanently destroys the seal and makes reinstatement impossible. Slide the bolt through the hole in the locking aperture and insert it into the barrel from beneath the hole. You’ll hear a ‘click’ sound as the bolt fixes itself into the barrel and is secured to the container. Check the seal by trying to pull apart the two pieces – it is not possible to re-open the seal with your hands so you can check the seal is closed by trying to pull the pin and barrel apart again.

A standard container has two doors, each fitted with locking bars with cams which lock into keepers located at the bottom of the container. The locking bars have handles with holes through which a seal can be attached to. The left door of the container is closed first, followed by the right door, so seals should be placed on the right-hand door for security.

Please note also, that you should be careful to only use barrier seals which have an anti-spin design. One of the known methods of defeating supposedly ‘tamper-evident’ bolt seals is by taking advantage of the free play of the pin available in inferior bolt seals – the pin is spun out of the barrel using a drill, allowing the seal to be opened and then re-sealed without signs of tampering. Our anti-spin designs prevent these kinds of attacks, as the pin cannot move completely freely.

Correct Location for Sealing Containers with Security Seals

The best location to seal the container is at the bottom of the right-hand door, where a security cam with a hole through engages into a special locking keeper. This is the most tamper-resistant location for placing of a security seal, and is the preferred location where available on containers with this anti-theft locking device. However, not every shipping container has this type of modification on the cam/keeper arrangement, and if not then the only other location where bolt seals should be placed is on the handle attached to the locking bar nearest to the door edge (i.e. the leftmost locking handle on the righthand door). It is not acceptable to seal the handles on the left-hand door, as the righthand door opens first.

Should I use More than One Container Seal?

There is no fixed rule on how many seals you should put on a shipping container, but every shipping container must have at least one seal located in one of the appropriate places. Technically there could be up to six places where seals can be sealed on a shipping container… It should be noted however, that seals do not actually prevent theft and pilferage – a committed thief with the appropriate tools can cut six seals just as easily as one!

Sealing and Recording Security Seal Use

If you are the sender of finished cargo loaded into FCL containers, and you are in a position to do so, we would always recommend that an authorised member of your team is present when the container doors are locked and the seal is applied – an image with time/date stamp can be really valuable in the event of discrepancies. Sending this image to the consignee is always good practice. Additionally, and particularly for LCL shipments, we would suggest that you ask your freight forwarders to send pictures of the seal (with seal number visible) on the container once sealed, again affixed with a date/time stamp. Such images can become very important in the event of loss or damage to cargo, as they can demonstrate to surveyors and insurance companies of the best practice of the parties to the insurance contract, and help them to determine the veracity of the claim.

Port and Customs Requirements for container seals

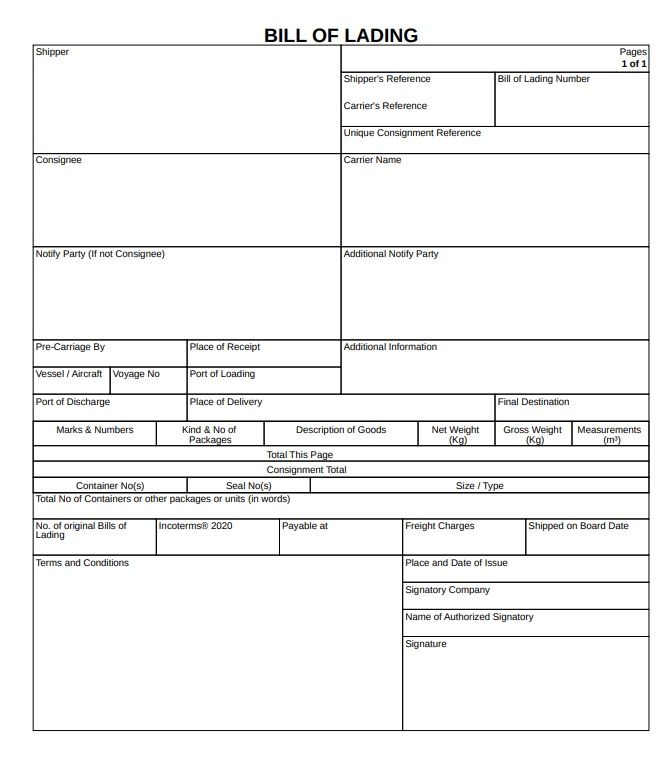

Shipping Lines and Bills of Lading

Shipping lines will only accept shipping containers for freight movements passing through customs borders with at least one container seal. The corresponding seal should be clearly noted on all road manifests, waybills and/or Bills of Lading to minimise the risk that shipments are delayed through the customs process. Bills of Lading provide key information about each shipping container movement, including shipping line, third parties, container ID number, weights/ classifications of contents, and also the seal number. As an interesting aside, it is thought that the very first Bills of Lading appeared for the first time in Spain, as early as 1544! An example Bill of Lading is shown below for illustration...

Customs Agencies and Security Container Checks

The Customs Department of respective national governments have the authority to conduct checks and random inspections on shipping containers passing through their jurisdiction at any time. During an inspection, any trader or freight forwarder security seal previously applied will be broken, so that the container and its contents can be checked against lodged customs paperwork and any discrepancies.

Once inspection is finished, it is likely that a prescribed ‘customs seal’ will be placed to re-secure the shipping container and to keep the contents safe on its ongoing journey. If you see an official customs seal applied to your container you know that your shipping container has been checked by customs authorities, rather than providing an indication that tampering has taken place.

If discrepancies or other issues with the shipping container has been discovered by customs authorities, they may apply one of a number of remedial steps in order to address the situation, which will depend precisely on the nature of the breach. It is important at this stage to take on board all of the customs authorities’ demands or requests, which may include deviating freight to onward freight handling terminals for further investigation, requests for additional customs duties, or other remedial action.

How Do You Remove a Container Seal?

It is suggested that the following steps are taken on receipt of a shipping container to ensure that no tampering has taken place:-

| step | DESCRIPTION |

|---|---|

| 1 | Before removing the seal, check for any signs of damage or wear or tear. In particular, check seal number engravings – are all characters uniform in size; are they are any signs of abrasion to the plastic on which markings are engraved; does the seal number on the pin of the seal correspond exactly to the barrel seal number? |

| 2 | The seal number on the container should obviously correspond to the bill of lading number and any other shipping documents presented by shipping lines or freight forwarders. If not, this discrepancy should be immediately raised and investigated with the shipping line. |

| 3 | If there is any evidence of tampering whatsoever, it is recommended that the seal should only be opened once the shipping line, freight forwarder and/or insurance representatives are present so that agreement is reached by all parties on the appropriate course of action. |

| 4 | If you see a customs seal on your container, you know that it has been opened by customs representatives, which is within their authority. You should follow any remedial steps that are requested in full to be compliant with local relevant regulations. |

| 5 | Container seals should be opened using bolt cutters of appropriate strength and size – the seal should be cut across the length of the pin. It is recommended that protective eyewear is worn for this operation, as the forces applied on cutting a seal are large and debris from the seal can be released at high velocity, causing potential injury to vulnerable parts of the body. |

What Should I do if My Container Seal is Broken or Missing?

A broken container seal indicates that cargo and goods inside the container may have been tampered or interfered with. If your container arrives with a broken or no seal, you should immediately contact the shipping line and their insurance company, for further investigation and a potential claim for compensation due to loss or damages pursuant to the any breach of contract.

If you do believe that you have been victim of a potential unauthorised tampering or interference attack, the best course of action is to act thoroughly and promptly:-

| STEP | DESCRIPTION |

|---|---|

| 1 | Take photos of the seal (if any) and the shipping container. |

| 2 | Immediately contact the shipping company, your freight forwarder and the company with which you have contracted your maritime transport insurance immediately. |

| 3 | Do not open the container until a representative of the shipping company is present. |

| 4 | Once the container has been opened, be sure to continue taking photos of the contents. This is very important in case you want to file a claim against the shipping company. |

If you found this article useful, please share with your colleagues and members of the shipping industry. You can also view all Container Security Seals in our range here, including our High-Security Locktainer 2020 Bolt Seals.

Types of Security Seals

The range and different types of security seals and tags can be confusing to the uninitiated, so we have produced the below quick visual guide for understanding some of the key differences, and how particular types of security seals might be suited to use cases in your organisation. For further help and assistance, please contact us at [email protected]

| .png) | .png) |

| Plastic Indicative Seals, 2 types: (1) Pull-Through Seals seal through locking chamber & pull progressively tighter, suitable for sealing of mail & cash bags; (2) Fixed Length Seals form a fixed loop, suitable where over-tightening might cause accidental breakage in transit (such as trailer hasps). | Security padlock seals are fixed length seals which are small and suitable for sealing of small enclosures like trolley apertures, first aid and other equipment kits, security bag zippers etc. They can easily be sealed and broken by hand for quick and convenient application. | Bolt security seals provide barrier control for shipping containers. They consist of a counterpart barrel and pin with duplicate numbering, sealed together and requiring bolt cutters to remove. They must meet ISO17712 high security standards and are suitable for cross-border customs movements. |

|  |  |

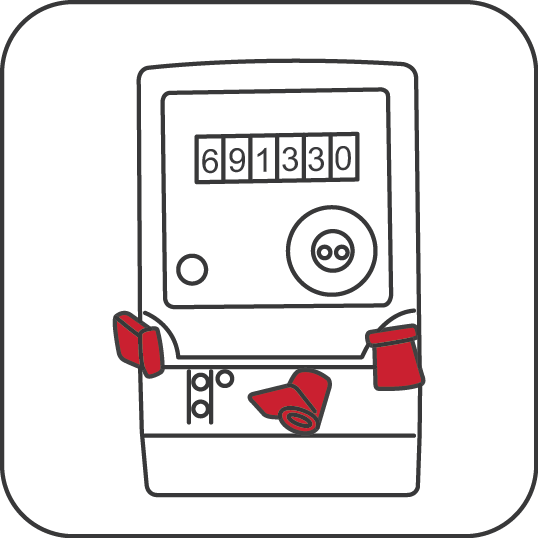

| Metal Cable seals are strong barrier seals, and in their heavier gauge options (Flexigrip 325M and Flexigrip 500M) are also ISO17712 'High Security' approved for customs movements. The pliable wire cable can be flexibly used to seal through hasps and around vertical locking bars, providing increased security. | Metal strip seals are useful option between plastic indicative seals and heavier duty cable and bolt seals - they provide a higher tensile strength of between 50KgF - 100KgF compared to plastic seals, but are most cost-efficient compared to cable and bolt seals. Their thin straps make them well-suited for sealing small apertures, such as TIR cords and railcars. | Meter wire seals are products suited to sealing utility (gas and electric) & taxi meters. They range from simple plastic and metal seals which can be crimped onto sealing wire with pliers, to more sophisticated self-locking seals with inner mechanism. Wire seals are produced with narrow gauge wire to fit through the small apertures of meters (<1mm). |

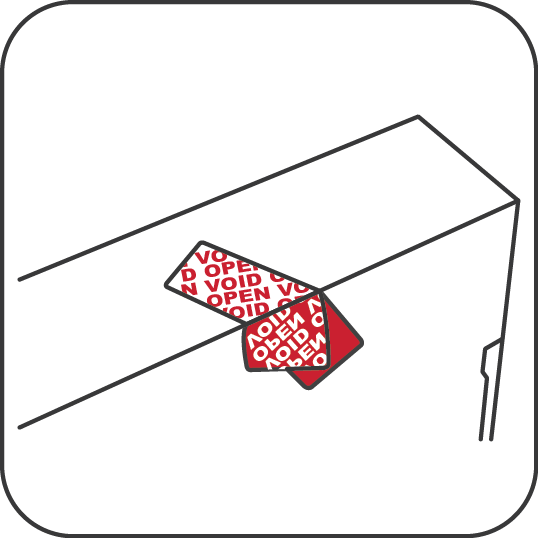

|  |  |

| Tote box plug seals are a specific type of fixed length seals designed to securely seal the lids of attached lid containers (ALC's) firmly shut. Plug seals seal down flush on to lids, making stacking of tote boxes easier, and can also be produced with paired numbering to seal both of end of the crate with the same security number. | Security labels and tapes are their own category of security seals which work on the basis of their tamper-evident film and adhesive properties, rather than by mechanical anti-tampering. By their nature, they are suitable for sealing flat surfaces, such as carton and pallet seams and edges. | Electronic seals are their own subset of security seals which use electronic sensors to detect a tamper-evident state. They are generally reusable seals with a higher initial cost which is spread over many thousands of uses. |

Our friendly and knowledge team would be happy to discuss your security seals needs - please contact us at [email protected] or +44 (0) 1829 76000.

What Exactly are Security Seals?

Definition of a Security Seal

Put simply, security seals provide a tamper-evident chain of custody for cargo and valuable assets in transit or in storage. They are devices that ‘seal’ enclosures to protect them from interference, maintaining the integrity of supply chains from loss, theft and other manipulation. Sealed enclosures can take many forms – including sacks, truck trailers, shipping containers and tote boxes – but what all enclosures share in common is that they encase sensitive items such as goods in transit and are the appropriate point to seal against unauthorised access.

Tamper-Evidence Function

Security seals, when used properly as part of a wider security protocol, serve two key functions. Firstly, they are tamper-evident or tamper-indicating, in that they are designed to permanently demonstrate physical evidence if interfered with – usually by tell-tale signs of breaking or other physical change of appearance, such as a ‘blushing’ on the surface of plastic seals when subject to manipulation or deformation.

These types of seals are sometimes simply called ‘indicative’ tamper-evident seals because their physical appearance indicates their status and that of the sealed enclosure. Indicative seals are easily broken or cut open with readily available light tools such as scissors. Indicative seals are used in many sectors, but commonly used to seal sacks and bags, domestic truck and trailer movements, fire extinguishers, roll-cages and crates.

Access Control Function

Security seals also serve a second access control function, reducing the occurrence of unauthorised access of sealed enclosures. They do this above all by their mere presence – well-placed seals serve as a psychological deterrence to access, simply by making individuals think twice about the consequences and what might happen should they ‘unseal’. Beyond this, a sub-category of seals called ‘barrier seals’ also provide an actual physical barrier to entry, acting like a specialised single-use lock which requires cutting tools to open, such as metal bolt and cable seals. Shipping containers, rail cars, and cross-border truck and trailer movements are the most common commercial uses for barrier security seals. Barrier seals physically prevent an illegitimate opportunist from opening the enclosure easily. These types of barrier seals are frequently referred to as ‘high security seals’ – these are security seals which meet the ISO17712:2013 ‘H’ ‘High-Security’ classification. This is an international standard setting out the strength, tamper-evident characteristics and other manufacturing standards which seals must meet in order to suitable for international customs movements, including US-bound consignments under C-TPAT regulations.

What security seals are not…

It can also be useful to define security seals by reference to what they are not.

Security seals are not just like padlocks. Keyed padlocks – often stronger than seals – are much more expensive, and also much more easily replaced. Unlike a security seal, most padlocks are not uniquely numbered or marked, so they can be broken and replaced leaving no sign that unauthorised access has occurred. Additionally, the key itself presents a problem – keys can be duplicated, borrowed, lost or simply unavailable when needed – and in each case this presents issues. Security seals can simplify security processes because they are low-cost, uniquely identifiable security devices which are designed to be sealed once and then broken once, at the appropriate times.

Nor are security seals just a different kind of cable tie. Cable ties are very different products and are ideal for particular use cases, but they should not be used as a security seal – cable ties can very readily be undone (and thereby re-tied in a matter of seconds…) because they have not been designed for tamper-evidence.

Security Seals Big and Small..

|  |

It is worth noting that security seals don’t come in any one particular form – they can range from simple void security labels or stickers suitable for application on flat enclosures such as pallets or carton seams, all the way up to heavy-duty metal construction container barrier seals...

…As long as it is a tamper-evident device which controls access to enclosures, then it is a security seal!

Universeal UK has been supplying security seals since 1992, and we are one of the leading organisations in the industry. Please email [email protected] for more information on our range and how we can assist. For advice on choosing the right security seal for your particular needs, please continue reading our next article in the series, Choosing the Best Security Seal for the Job.

This article is the first of four, looking at how security seals can fit within your wider security protocols. View Series below...

- What are Security Seals?

- Choosing the Best Security Seal for the Job

- Security Protocols: Making Security Seals work for you

- Glossary – Understanding security seal terminology